FIGURES

-

Approximately 1,000 leg amputees in Ireland are between the ages of 1 and 12.

-

Between the ages of 1 and 5 a child will have to change their prosthetic limb once a year.

-

At age 5-12 change of prosthetic will occur once every 1-2 years.

-

From age 12 to 21 a change in prosthetic will be required every 3-4 years.

These figures indicate the need for between 10 and 15 prosthetics throughout childhood

-

A below the knee prosthetic limb that would allow a patient to walk on flat ground costs between 4,500 and 6000 euro

-

A below the knee prosthetic limb allowing a patient to navigate bumpy ground and stairs costs approximately 9,500 euro

-

A below the knee prosthetic limb allowing the patient to walk and run as well as a non amputee costs approximately 14,000 euro

Gro was a team based project in which we had 8 weeks to find a market, produce a design and base a business plan around it. This was then to be entered into competiton competing against other teams with backgrounds in a range of disciplines.

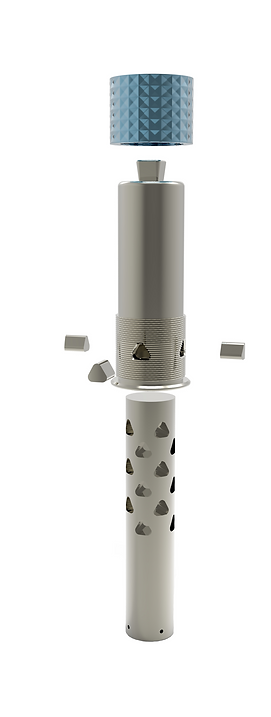

Original Design

Refining of new concept

Original Design: Cian Hamilton, John Kelly, Matthew Gaughran, Eoin Cummins.

New Design: John Kelly

Business Plan: John Kelly, Cian Hamilton, Matthew Gaughran, Eoin Cummins.

Features

*please note that socket and foot prosthetics are not my own and are shown for reference only

Insert the anchors to hold the inner and outter pylon in position at the desired height

Fit the inner pylon into the outter pylon and set at desired height

Lock pylon in position by secureing the lock nut in place

Inner Pylon

Anchors

Outter Pylon

Lock nut

Inverted pyramid is the standard joint used in prosthetics to connect parts such as socket and pylon in this instance

At the bottom is the receiving end for an inverted pyramid. An ankle/foot can be attached here and is fixed with grub screws

Business Model Canvas

Key Activities

Key Partners

Value Propositions

Key Resources

Channels

Customer Relationships

Customer Segments

-

Health Service Executive Ireland

-

disAbility.ie

-

Amputee.ie

-

Cappagh National Orthopaedic Hospital

-

Prosthetists

-

Manufacturing and distributing companies

-

Design & production

-

Networking

-

Marketing to raise awareness

-

Developing relationships to aid distribution

-

Organising events

-

Performance

-

Long term Value

-

Price

-

Convenience & Usability

-

Follow up care

-

Product gaurantee

-

Close customer relationship with post purchase assistance and care in association with key partners

-

Personal assistance

-

Follow up care in conjunction with prosthetist recommendations

-

Trust

-

Frontline staff and design team

-

Engineering team

-

Key Partners

-

Enterprise Ireland for kickstart funding

-

Investors

-

Possible Intellectual property

-

Healthcare workers e.g. prosthetists

-

Hospitals and clinics

-

Prosthetist's and orthopaedic specialsts

-

Online amputee websites such as amputee.ie

-

Younger amputees who are still growing

-

Adolescents who are prone to growth spurts

-

Active amputees who wish to get a quality prosthetic that will last longer

Cost Structure

-

Based on value driven sentiment by reducing turn over of prosthetic legs for an amputee.

-

Includes overheads per unit such as space rental, electricity etc.

-

Provides long term savings for customer

Revenue Streams

-

Through sale of product and retention of customers

-

"Buy Back" scheme to save money on material by reusing and recycling used product

Approximately 1,000 leg amputees in Ireland are between the ages of 1 and 21. In the UK this number is approximately 12,800.

Approximately 148,500 amputees in mainland Europe between the ages of 1 and 21.

Approximately 63,200 leg amputees in the U.S. are between the ages of 1 and 21

Year 7 onwards

Year 1 - 3

Year 4 - 6

Marketing & Distribution

Concept exploration for new design

The original design uses basic mechanical fixings to hold the inner and outer pylon together. By using a lock nut against the outer pylon the idea was to wedge the two parts together to insure a tight fit. However, while this idea gave the ability to minutely adjust the height of the leg, upon further investigation myself I found that torsion forces may cause the mechanical fixing to open and the pylons to become loose. I then decided to explore concepts further to enhance the solution